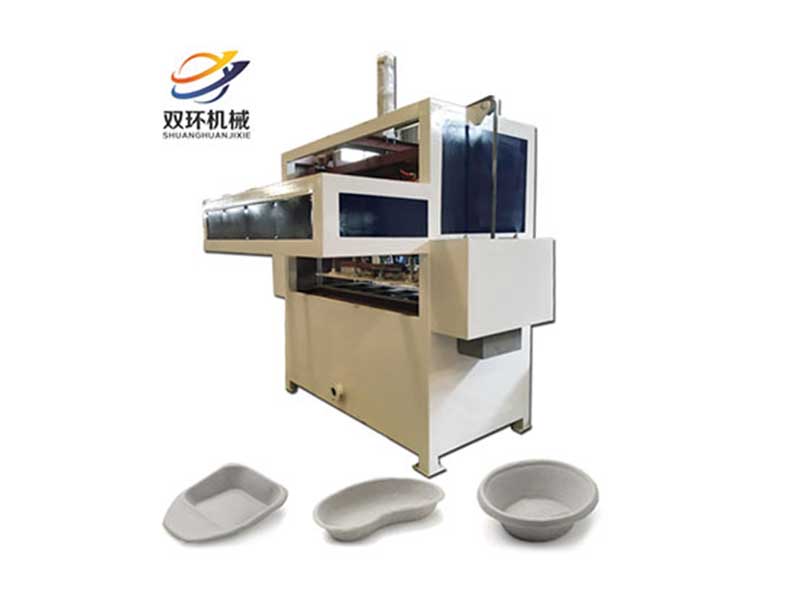

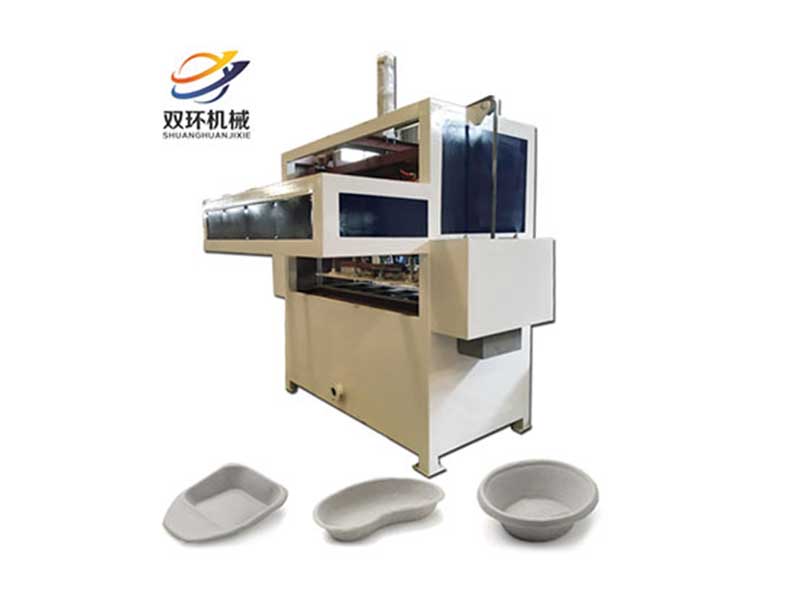

一次性醫用耗材紙尿盆尿壺生產設備

Fully automatic industrial inner packaging paper tray forming machine

半自動紙漿模塑成型機 型號SHW-700/1000A

Semi automatic pulp molding machine SHW-700/900A

4面回轉式紙漿模塑機 型號SHZG-2000

Fully automatic 4 plane rotary pulp molding machine SHZG-2000

自動成型設備,成型產品自動進入烘干線干燥。

It’s a composed of forming machine and drying line, after forming, the products will enter into drying line for drying automatically.

成型產品不需要人工中轉,節省工人,生產效率高。

The forming products don’t need to be transferred by labors, so it can save labor, and has high efficiency.

可用于各種較大批量的紙模產品生產。

It is a applicable to manufacturing large quantity of pulp molding products.

全自動工業內包裝紙托生產工藝流程簡圖

Schematic diagram of fully automatic industrial inner packaging paper tray production line

基本配置表 Basic allocation sheet

|

型號 Model |

產能 Capacity |

成型機 Forming machine |

烘干線 Drying line |

建議車間尺寸 Workshop size recommendation |

全套設備裝機容量 Power requirement |

|

SHW-700A |

50-60kg/h |

往復移出式主機Reciprocating machine 模板尺寸Plate size 1600*400mm |

16m*2.6m*3m |

長度length≥30 寬度width≥10m |

100KW |

|

SHW-1000A |

80-100kg/h |

往復移出式主機Reciprocating machine 模板尺寸 plate size 1600*800mm |

26m*2.6m*3m |

長度length≥40m 寬度width≥8m |

160KW |

|

SHZG-2000A |

120-150kg/h |

4面回轉式主機4 plane rotary machine 模板尺寸 plate size 1450*450mm |

26m*3.4m*3m |

長度length≥40m 寬度width≥15m |

200KW |

|

1.設備以產品干重150-200g為計算依據。 Capacity of the equipment is based on the product weight 150-200g/pc. 2.其他產能,可根據客戶的試機要求專門進行設備配置。 For different capacity customized allocation according to clients’ requirement is available. 3.車間尺寸供參考,可以根據客戶實際車間大小稍微調整設備布局。 Workshop size for reference only, and can be slightly adjusted according to actual size of client’s plant. |

|||||

產品型號圖

2019 © Copyright.湖南雙環纖維成型設備有限公司 地址: 湖南省湘潭市德國工業園萊茵路6號 備案號: 湘ICP備17015724號-1 營業執照查閱

技術支持:競網智贏